Aftermarket Rear Disc Brakes Installation

by George Nenadovich

Here is the stock 1972 Skylark 8.5" corporate rear axle.

This unit was removed from a 72 Skylark 4dr and has the two "cut outs"

at the 9 and 3 o'clock positions as indicated by the arrows. You can also

find these rears in the 71-2 Skylarks and Cutlass models. Other models such

as LeMans, Monte Carlo, Chevelle, Grand Prix can also have this rear axle.

They are 28 spline, non C-clip rears (bolt in axle shafts) and called corporate

rears since you can use the center section from any 71-88 GM car, van, truck

with the 8.5" center section.

Here is the stock 1972 Skylark 8.5" corporate rear axle.

This unit was removed from a 72 Skylark 4dr and has the two "cut outs"

at the 9 and 3 o'clock positions as indicated by the arrows. You can also

find these rears in the 71-2 Skylarks and Cutlass models. Other models such

as LeMans, Monte Carlo, Chevelle, Grand Prix can also have this rear axle.

They are 28 spline, non C-clip rears (bolt in axle shafts) and called corporate

rears since you can use the center section from any 71-88 GM car, van, truck

with the 8.5" center section.

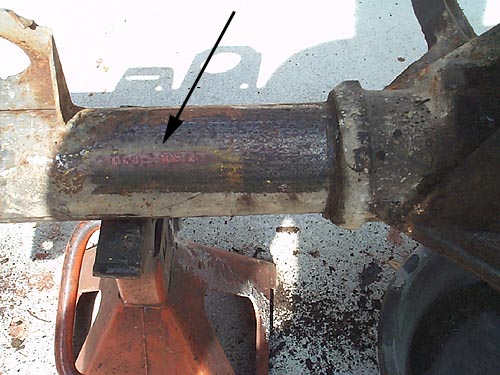

This shows the pinion yoke. The earlier rears are 8.2"

and use U-bolts w/nuts to retain the driveshaft u-joint to the pinion yoke.

The 8.5" rears use screws w/straps as shown in the pic. This is the

easiest way to identify the corporate 8.5"

This shows the pinion yoke. The earlier rears are 8.2"

and use U-bolts w/nuts to retain the driveshaft u-joint to the pinion yoke.

The 8.5" rears use screws w/straps as shown in the pic. This is the

easiest way to identify the corporate 8.5"

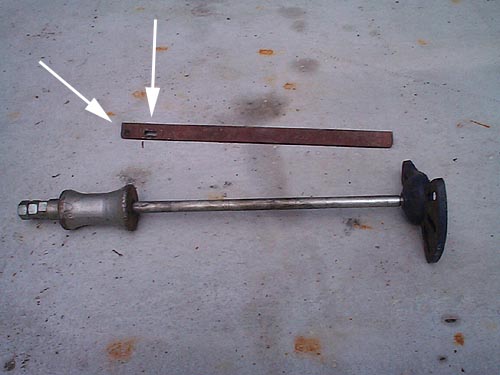

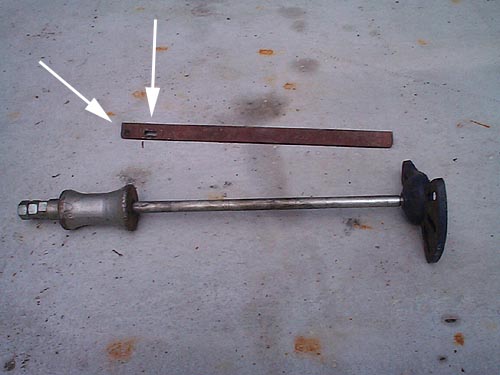

Here are a couple "special" tools you need to disassemble

a rear. The bottom one is called a "slap hammer" or inertia puller.

There are 4 nuts that hold the axle flange to the axle tube. There are 3

holes in the axle flange so you can slide a 9/16" hex head socket through

it to remove the 4 nuts. Simply attach the right end axle flange (slotted

to slide over a wheel stud) and use a lug nut to hold it in place. Slide

the hammer back a few times and the axle will come out of the axle tube.

Repeat the process for the other side. The top tool is a pinion stop I fabricated

from some angle iron. See below for more detail.

Here are a couple "special" tools you need to disassemble

a rear. The bottom one is called a "slap hammer" or inertia puller.

There are 4 nuts that hold the axle flange to the axle tube. There are 3

holes in the axle flange so you can slide a 9/16" hex head socket through

it to remove the 4 nuts. Simply attach the right end axle flange (slotted

to slide over a wheel stud) and use a lug nut to hold it in place. Slide

the hammer back a few times and the axle will come out of the axle tube.

Repeat the process for the other side. The top tool is a pinion stop I fabricated

from some angle iron. See below for more detail.

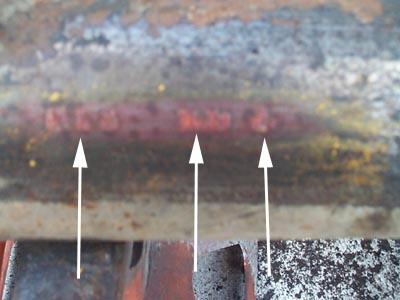

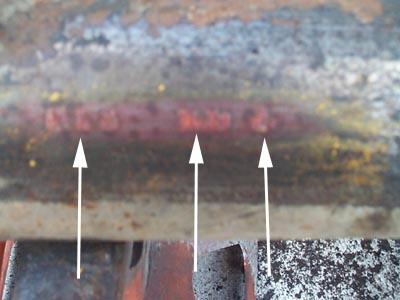

Here is the axle code stamped on the passenger side axle

tube. It is very hard to read and I had a hard time getting the camera to

show the digits/letters clearly. The first arrow points to the axle code

which is LKB. This, LK, indicates the gear ratio of 2.56 and non-posi. The

B stand for Buick rear manufacturer.Other letters are O for Olds, P for

Pontiac, GF for Chevy Gear and Axle, C for Chevy Buffalo, K for GM of Canada,

W for Chevy Warren. The next arrow points to the day of the year which is

109. The 109th day would be second week of April. The last digit is 2 for

second shift.

Here is the axle code stamped on the passenger side axle

tube. It is very hard to read and I had a hard time getting the camera to

show the digits/letters clearly. The first arrow points to the axle code

which is LKB. This, LK, indicates the gear ratio of 2.56 and non-posi. The

B stand for Buick rear manufacturer.Other letters are O for Olds, P for

Pontiac, GF for Chevy Gear and Axle, C for Chevy Buffalo, K for GM of Canada,

W for Chevy Warren. The next arrow points to the day of the year which is

109. The 109th day would be second week of April. The last digit is 2 for

second shift.

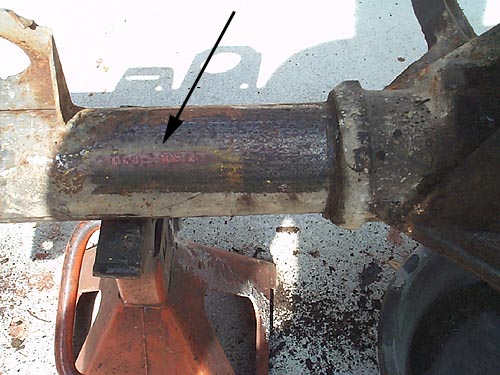

A wider view to show the location of the numbers/letters

in reference to the passenger spring perch and center pumpkin.

A wider view to show the location of the numbers/letters

in reference to the passenger spring perch and center pumpkin.

Here is the axle completely stripped, wire brushed, sanded

and painted. The center section is natural cast iron while the axle tubes

are black. This axle was completely disassembled for gear change, posi installation,

rear disc brakes and for a body-off restoration.

Here is the axle completely stripped, wire brushed, sanded

and painted. The center section is natural cast iron while the axle tubes

are black. This axle was completely disassembled for gear change, posi installation,

rear disc brakes and for a body-off restoration.

Here is the posi for this rear axle. This unit was removed

from an 85 Electra wagon with the 8.5" rear.

Here is the posi for this rear axle. This unit was removed

from an 85 Electra wagon with the 8.5" rear.

The pinion nut is 1.25" and usually requires a great

amount of torque to break loose. The pinion stop pictured above works great

on this and in the salvage yards when removing 8.5" posi units and

pinion gears as mentioned previously from the 85 Electra. The angle iron

can be any length but I made mine about 27" long so it can fit in my

salvage yard tool box. I also slotted one of the holes to fit several different

pinion screw spacing. Simple remove two screws and the strap from the pinion.

Place the pinion stop over the pinion and reinstall the pinion screws. Now,

use a 1/2" breaker bar and 1.25" hex socket to break the pinion

nut loose. The pinion bar will prevent the pinion and yoke from turning

as you loosen the pinion nut. Place your hand inside the pumpkin and hold

the pinion before you completely remove the nut. If you don't the pinion

can fall out and get damaged.

The pinion nut is 1.25" and usually requires a great

amount of torque to break loose. The pinion stop pictured above works great

on this and in the salvage yards when removing 8.5" posi units and

pinion gears as mentioned previously from the 85 Electra. The angle iron

can be any length but I made mine about 27" long so it can fit in my

salvage yard tool box. I also slotted one of the holes to fit several different

pinion screw spacing. Simple remove two screws and the strap from the pinion.

Place the pinion stop over the pinion and reinstall the pinion screws. Now,

use a 1/2" breaker bar and 1.25" hex socket to break the pinion

nut loose. The pinion bar will prevent the pinion and yoke from turning

as you loosen the pinion nut. Place your hand inside the pumpkin and hold

the pinion before you completely remove the nut. If you don't the pinion

can fall out and get damaged.

This is the aftermarket kit sold by TSM, for more info

you can visit TSM Website

for more info.

The kit is basically a bolt-on set-up using new rotors, caliper

brackets, e-brake adapters and rubber flex hoses. The items not shown for

this kit are the 80-85 Seville, Toronado, Eldorado, Riviera. The only items

require a little more effort to install are the brake hose brackets which

will be welded to the axle tube.

This is the aftermarket kit sold by TSM, for more info

you can visit TSM Website

for more info.

The kit is basically a bolt-on set-up using new rotors, caliper

brackets, e-brake adapters and rubber flex hoses. The items not shown for

this kit are the 80-85 Seville, Toronado, Eldorado, Riviera. The only items

require a little more effort to install are the brake hose brackets which

will be welded to the axle tube.

Here is the caliper bracket mounted to the axle flange and

the spacer plate is used to replace the old factory backing plate.

Here is the caliper bracket mounted to the axle flange and

the spacer plate is used to replace the old factory backing plate.

Rear shot of the caliper bracket. Notice the caliper bracket

bosses face the axle flange. If you have the smooth side facing the axle

flange, you will not be able to get the caliper on the rotor.

Rear shot of the caliper bracket. Notice the caliper bracket

bosses face the axle flange. If you have the smooth side facing the axle

flange, you will not be able to get the caliper on the rotor.

These are the weld on hose brackets to replace the factory

hard line to the wheel cylinders. The calipers use a rubber hose which will

pass through these holes and have a "U" clip hold them in place.

You will have to shorten the factory hard line and reflare. See pic below

of completed installation!

These are the weld on hose brackets to replace the factory

hard line to the wheel cylinders. The calipers use a rubber hose which will

pass through these holes and have a "U" clip hold them in place.

You will have to shorten the factory hard line and reflare. See pic below

of completed installation!

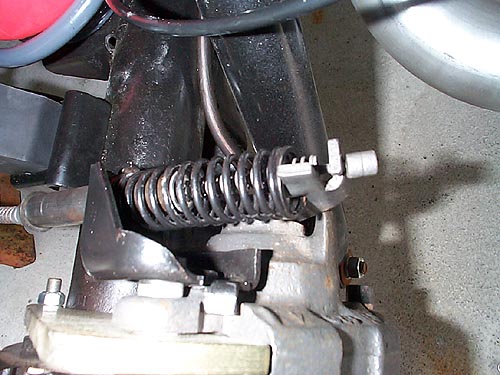

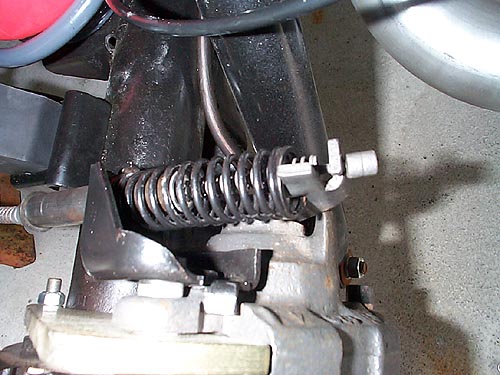

Here is an almost complete installation using the 80-5 Seville,

Eldorado, Riviera, Toronado rear brake calipers with e-brake lever. I have

not welded the hose bracket in this pic.

Here is an almost complete installation using the 80-5 Seville,

Eldorado, Riviera, Toronado rear brake calipers with e-brake lever. I have

not welded the hose bracket in this pic.

Here is a 15" Buick rallye wheel mounted on the rear

axle to test caliper-to-rim clearance. Notice there is approximately 1/2"

clearance. Other kits that use the F-body (Camaro/Firebird) calipers, you

will need to use a file to trim the cooling fins to run stock 15" rims.

The later F-body set-ups use 16" wheels so the cooling fins are not

close on those newer models.

Here is a 15" Buick rallye wheel mounted on the rear

axle to test caliper-to-rim clearance. Notice there is approximately 1/2"

clearance. Other kits that use the F-body (Camaro/Firebird) calipers, you

will need to use a file to trim the cooling fins to run stock 15" rims.

The later F-body set-ups use 16" wheels so the cooling fins are not

close on those newer models.

Here is the complete installation. Arrow indicates welded

on tab to hold new disc brake hose to hard line. You will need to shorten

the existing lines and re-flare the ends. Brake hose is Coni-Seal BH177024

which cross references to Wagner 97661, Midas 2320, EIS 5494, Bendix 77024,

Auto Spec 87011.

Here is the complete installation. Arrow indicates welded

on tab to hold new disc brake hose to hard line. You will need to shorten

the existing lines and re-flare the ends. Brake hose is Coni-Seal BH177024

which cross references to Wagner 97661, Midas 2320, EIS 5494, Bendix 77024,

Auto Spec 87011.

These are the e-cable spacers for the rear calipers. The

drum brake e-cables are longer than the non-original disc brake versions

so these remove the slack from the cables.

These are the e-cable spacers for the rear calipers. The

drum brake e-cables are longer than the non-original disc brake versions

so these remove the slack from the cables.

The arrows indicate the approximate length dimension points

when installed on a rear drum brake car, about 3.5-3.75"

The arrows indicate the approximate length dimension points

when installed on a rear drum brake car, about 3.5-3.75"

Here is the one sleeve installed on the lower e-brake cable.

It is 2.5" long and required no trimming.

Here is the one sleeve installed on the lower e-brake cable.

It is 2.5" long and required no trimming.

Here is the disc brake e-cable brkt removed from the caliper.

The sleeve has been shortened so the right side extends 1.375" from

the end of the bracket. The silver retainer is then installed using a 9/16"

deep socket and hammer to tap the retainer in place.

Here is the disc brake e-cable brkt removed from the caliper.

The sleeve has been shortened so the right side extends 1.375" from

the end of the bracket. The silver retainer is then installed using a 9/16"

deep socket and hammer to tap the retainer in place.

Here is the cable installed with the large sleeve over the

smaller sleeve.

Here is the cable installed with the large sleeve over the

smaller sleeve.

Here is the original Eldorado spring installed over the original

e-brake cable for proper e-brake

operation.

Here is the original Eldorado spring installed over the original

e-brake cable for proper e-brake

operation.