We ran into two interesting problems recently that appear to affect

high

lift cams in the Buick 455 engines:

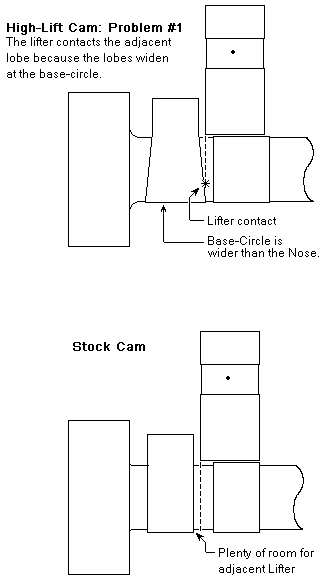

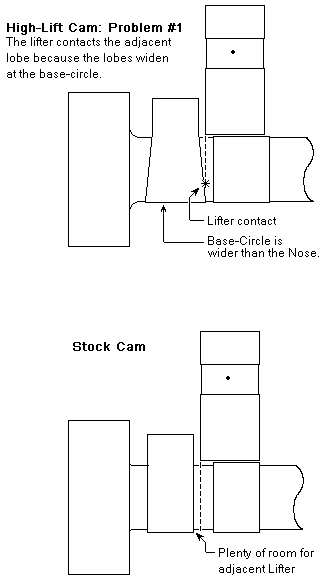

Problem #1: Some cam lobes are ground wider at the base circle than

at the

nose. This causes the possibility of lobe interference with the adjacent

lifter. (See attached drawings).

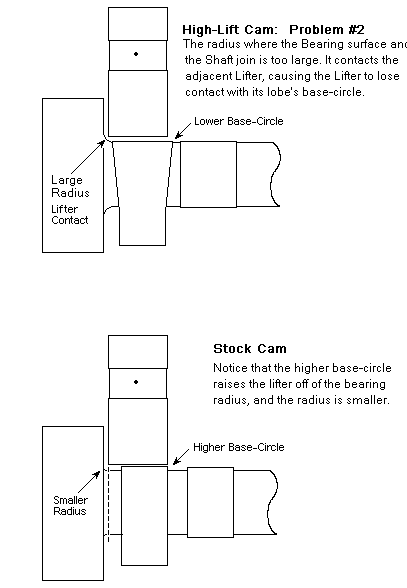

Problem #2: In order to achieve high lift you have to greatly reduce

the

base circle of the lobe due to the very small diameter of the Buick cam.

This creates the possibility of #3 bearing journal interference with the

adjacent lifter.(See attached drawings).

Note: I've seen some

cams that had the body (shaft) of the cam cut down

between lobes so that there was a very well defined lobe profile even

around the base circle, and I've seen other cams that did not have a well

defined base circle.

I compared some new high-lift cams to some older high-lift cams that we've

run in the past (in various other blocks) and I found evidence of the same

interference problems on all of them (galling). All of these cams were in

the .600 lift range and they came from different manufacturers. All were

solids but the problem would also exist on hydraulic cams as well. We

installed each of them into one block so we could physically see the

problems and compare all the cams. I don't know the minimum lift at which

the interference problems will occur, but we installed a pure stock cam

into this same block for comparison. As expected there was no interference

problem with the stock cam... everything cleared easily! Since the stock

cam works well, we know we're not dealing with core-shift issues.

Figure #1 shows the problem when the base circle is cut wider than the

nose of the lobe. In some cases, a lifter can start to ride up on the ramp

of the next lobe (adjacent lobe), which will cause the lifter to skip over

it's own base circle. At the very least, this will cause an erratic opening

of the valve and some loss of power. At the most, the interference between

the lifter and the adjacent lobe can destroy a lifter, a cam, and possibly

even an engine! (We've seen one case recently in which this happened!)

Figure #2 shows another problem. This problem occurs when the base circle

is ground down to the point where you can no longer (or just barely)

distinguish it from the body (shaft) of the cam itself to obtain the

higher lift. Due to the close proximity of #5 exhaust lobe to the # 3 cam

bearing journal, the lifter on #5 exhaust will actually catch the cam bearing

journal which will cause the lifter to actually lift off the base circle

of its lobe. I have looked at several cams that have been run in the past

and they all show signs of galling into the lower radius of the #3 cam bearing

journal. Again, this causes an incorrect pattern on that particular valve

since the lifter never touches its own base circle, resulting in a loss

of power and possible damage.

I would like others to look at large lift cams that they have run and see

if this problem shows up on theirs as well.

This IS NOT intended to slam any cam manufacturer's product!

It is intended to inform everyone of a problem that does exist in our

engines. It is relatively simple to correct the problem.