How To Recover Bucket Seats

by George Nenadovich

Here is a bucket seat that is going into a 72 Skylark coupe

that had a bench seat. This particular seat came from a 1972 Cutlass. The

headrest was missing and the rest of the seat is in good condition. These

seats can be found in GM A-bodies from 1968-72 including Cutlass/442, Chevelle/SS,

LeMans/GTO, 70-2 Monte Carlo, 70-2 Grand Prix and X-body 68-72 Nova. They

can also be found in full size cars(B-body) such as Rivera, Toronado, Wildcat

but the legs will have a different configuration. In order to place buckets

in a bench seat car, you will need to order the bucket seat brackets to

weld to the floor. Power bucket seats use different floor brackets than

manual seats.

Here is a bucket seat that is going into a 72 Skylark coupe

that had a bench seat. This particular seat came from a 1972 Cutlass. The

headrest was missing and the rest of the seat is in good condition. These

seats can be found in GM A-bodies from 1968-72 including Cutlass/442, Chevelle/SS,

LeMans/GTO, 70-2 Monte Carlo, 70-2 Grand Prix and X-body 68-72 Nova. They

can also be found in full size cars(B-body) such as Rivera, Toronado, Wildcat

but the legs will have a different configuration. In order to place buckets

in a bench seat car, you will need to order the bucket seat brackets to

weld to the floor. Power bucket seats use different floor brackets than

manual seats.

Here are some simple hand tools required to recover the seats.

The top tool is hog ring pliers. These are special pliers for bending the

hog rings into a circle. When you buy the rings they are shaped like the

letter "C". The bottom tool is chain (bolt) cutters to remove

the old hog rings.

Here are some simple hand tools required to recover the seats.

The top tool is hog ring pliers. These are special pliers for bending the

hog rings into a circle. When you buy the rings they are shaped like the

letter "C". The bottom tool is chain (bolt) cutters to remove

the old hog rings.

Here is a close up of the hog rings. You can buy these from

most aftermarket A-body suppliers or any auto trim shop.

Here is a close up of the hog rings. You can buy these from

most aftermarket A-body suppliers or any auto trim shop.

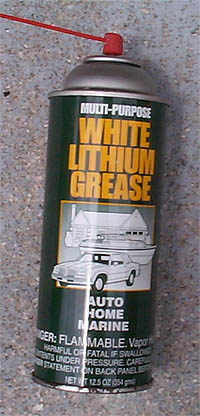

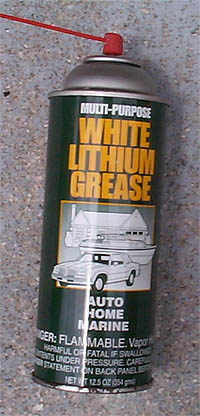

This is some spray grease that I use to lubricate the sliders.

Each slider has four ball bearings. Spray grease on each one to ensure smooth

sliding action!

This is some spray grease that I use to lubricate the sliders.

Each slider has four ball bearings. Spray grease on each one to ensure smooth

sliding action!

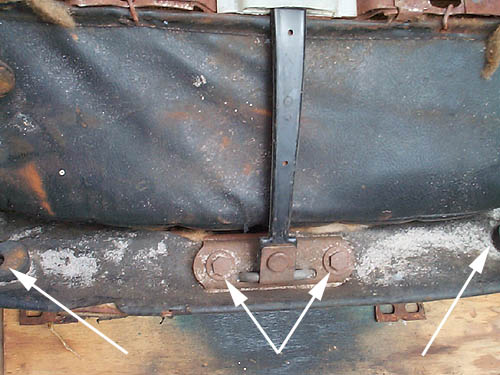

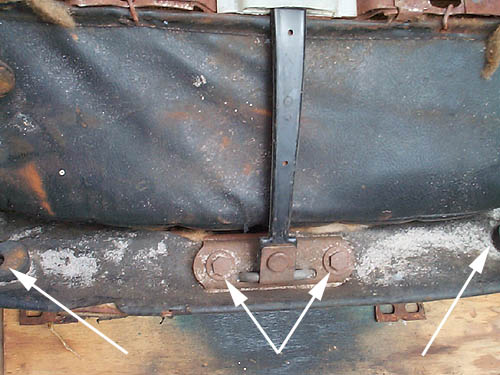

Remove the lower plastic skirts. Each is held in place by

three Phillips screws, two on the front and one on the lower rear side.

Remove the chrome push button seat back release from the upper plastic back

plate. Use a large flat blade screwdriver or large putty knife to gently

pry up the button. With the button removed, you will see two screws that

need to be removed. Also on the bottom edge just to the right of the upper

back cushion guide will be another Phillips screw. Remove that screw and

slide the plastic back panel up. On the the lower seat cushion as shown

above, remove the two rubber bumpers shown by the far left and far right

arrows. They are held in place by a Phillips screw. Now, remove the upper

cushion retainer strap, center arrows, it is held in place with two 7/16"

hex head screws.

Remove the lower plastic skirts. Each is held in place by

three Phillips screws, two on the front and one on the lower rear side.

Remove the chrome push button seat back release from the upper plastic back

plate. Use a large flat blade screwdriver or large putty knife to gently

pry up the button. With the button removed, you will see two screws that

need to be removed. Also on the bottom edge just to the right of the upper

back cushion guide will be another Phillips screw. Remove that screw and

slide the plastic back panel up. On the the lower seat cushion as shown

above, remove the two rubber bumpers shown by the far left and far right

arrows. They are held in place by a Phillips screw. Now, remove the upper

cushion retainer strap, center arrows, it is held in place with two 7/16"

hex head screws.

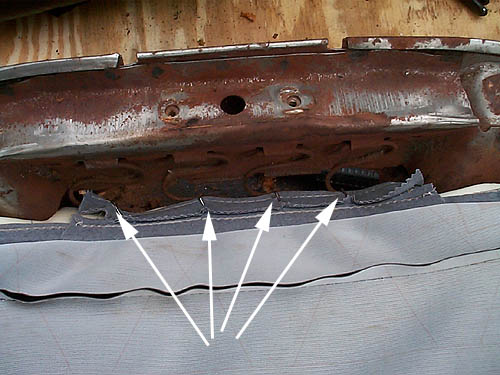

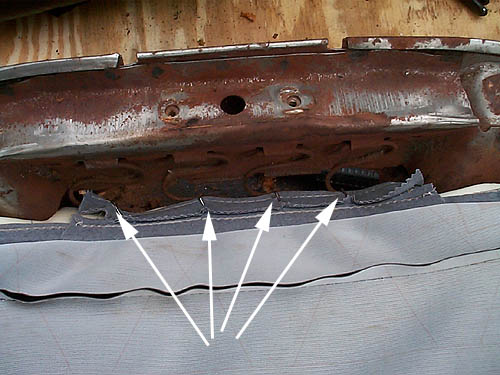

Cut the hog rings indicated by the the right lower arrows

with the bolt cutter. This will reveal the side hinge screws, 1/2"

hex head. Remove the screws on both sides and set aside the upper cushion.

Cut the hog rings indicated by the the right lower arrows

with the bolt cutter. This will reveal the side hinge screws, 1/2"

hex head. Remove the screws on both sides and set aside the upper cushion.

Now go around the lower seat cushion perimeter and cut all

hog rings. Remove the seat cover and old foam. Pictured above is the burlap/cloth

cover that rests between the foam and springs. This one is shot and will

be replaced. Best solution I have found is to use a piece of house carpet

that has a burlap or jute backing. Now is the time to inspect all springs

and make repairs. You can buy replacement spring kits if needed.

Now go around the lower seat cushion perimeter and cut all

hog rings. Remove the seat cover and old foam. Pictured above is the burlap/cloth

cover that rests between the foam and springs. This one is shot and will

be replaced. Best solution I have found is to use a piece of house carpet

that has a burlap or jute backing. Now is the time to inspect all springs

and make repairs. You can buy replacement spring kits if needed.

Here is the new lower seat cushion foam. If your seats are

original, you should replace the foam due to age and wear. Putting new covers

over old foam will not feel like a new seat and may not fill the seat covers

to give a smooth finished look, you do not want the seat covers to be lumpy

or wrinkled.

Here is the new lower seat cushion foam. If your seats are

original, you should replace the foam due to age and wear. Putting new covers

over old foam will not feel like a new seat and may not fill the seat covers

to give a smooth finished look, you do not want the seat covers to be lumpy

or wrinkled.

Here is the lower seat cover put in position and anchored

to the seat springs. This is your starting point for installing the hog

rings. On new seat covers, the seam has a plastic rod sewn in place. On

the old covers, there is a corrugated rod. If your new covers do not have

the plastic rod, you will have to reuse your old one. So, don't throw out

your seat covers until you complete the seats.

Here is the lower seat cover put in position and anchored

to the seat springs. This is your starting point for installing the hog

rings. On new seat covers, the seam has a plastic rod sewn in place. On

the old covers, there is a corrugated rod. If your new covers do not have

the plastic rod, you will have to reuse your old one. So, don't throw out

your seat covers until you complete the seats.

This is the orignal corrugated rod as discussed above.

This is the orignal corrugated rod as discussed above.

Here is the lower cushion flipped upside down. The middle

arrow or right arrow shows the next anchor point that has to be installed

with hog rings. After completing these three hog rings, work your way around

the perimeter making sure you have no wrinkles. Also, notice the carpet

on the seat springs that replaced the old burlap that was worn out. These

section is done. Notice the loose material on the left. This must be left

alone until the upper seat cushion is attached to the lower section. The

material will cover the hinge bolts and give a smooth finished look to the

seat. Use hog rings to cover the hinges, only two are required to join material

sections. The last item to install is the plastic trim panels.

The process is the same for the upper cushion. Take your

time and do one seat at a time so you can use the old one as reference in

case you forget where the anchor points are for each hog ring.

Here is the lower cushion flipped upside down. The middle

arrow or right arrow shows the next anchor point that has to be installed

with hog rings. After completing these three hog rings, work your way around

the perimeter making sure you have no wrinkles. Also, notice the carpet

on the seat springs that replaced the old burlap that was worn out. These

section is done. Notice the loose material on the left. This must be left

alone until the upper seat cushion is attached to the lower section. The

material will cover the hinge bolts and give a smooth finished look to the

seat. Use hog rings to cover the hinges, only two are required to join material

sections. The last item to install is the plastic trim panels.

The process is the same for the upper cushion. Take your

time and do one seat at a time so you can use the old one as reference in

case you forget where the anchor points are for each hog ring.

Wow, what a difference!

Total installation time was about one hour per section or

four hours total to do both seats.

Wow, what a difference!

Total installation time was about one hour per section or

four hours total to do both seats.

Costs

Seat Covers $250/pr

Seat Foams $100/set

Head Rests $140/pr

Seat Back Button $ 36/pr

Hog Rings w/pliers$ 21

Headrest Releases $ 37/set of four

Seat Backs $ 70/pr

Seat Skirts $ 40/pr, two pairs required

Manual Seat brkts $ 22/pr

P.seat brkts $ 75/pr

Seat chrome trim $ 17

Chrome end caps $ 16/set

As you can see from the prices listed above, you can easily spend

over $600 to recover/restore a pair of bucket seats. It is always a good

idea to start with the best condition used seats that you can find for a

reasonable price or find some that may already be recovered.