New Edelbrock Performer 455 Buick Heads

by George Nenadovich

Pics of bare aluminum Edelbrock heads, part#60039, assembled

versions are #60049

Edelbrock states your compression will increase to 9.2 from

8.5:1 when installing these heads. They recommend 9.650 pushrods, stock

ones will not work. If you have other questions, contact Edelbrock tech

800-416-8628

Pics of bare aluminum Edelbrock heads, part#60039, assembled

versions are #60049

Edelbrock states your compression will increase to 9.2 from

8.5:1 when installing these heads. They recommend 9.650 pushrods, stock

ones will not work. If you have other questions, contact Edelbrock tech

800-416-8628

Flow numbers provided by Mike at TA Performance.

TA converted iron heads to Stage 1, Edelbrock, TA Stage1SE

Intake Flow Numbers CFM

Lift Iron Intake Edelbrock TA SE

.050” 033.2 033.2 035.0

.100” 066.2 068.3 069.9

.200” 133.5 130.5 140.4

.300” 188.2 194.2 194.2

.400” 225.8 250.9 249.1

.450” 233.6 269.9 273.1

.500” 236.0 278.4 285.3

.550” 236.0 280.8 291.9

.600” 233.6 283.2 289.7

.650” 233.0 282.0 278.6

.700” 233.0 280.8 280.8

Exhaust Flow Numbers CFM

Lift Iron Exhaust Edelbrock TA SE

.050” 028.3 024.4 027.5

.100” 056.6 055.0 058.9

.200” 109.4 107.0 112.5

.300” 132.8 143.7 160.6

.400” 146.9 163.8 190.3

.450” 156.0 170.0 199.6

.500” 159.1 171.6 205.9

.550” 159.1 174.7 209.0

.600” 159.1 174.7 210.6

.650” 162.2 174.7 210.6

.700” 162.2 174.7 210.6

Note: Edelbrock heads are the only ones with some clean up work in the bowls. That’s how they came.

TA heads respond very well to this type of clean up. Iron heads are a little touchier, but will

respond if done right.

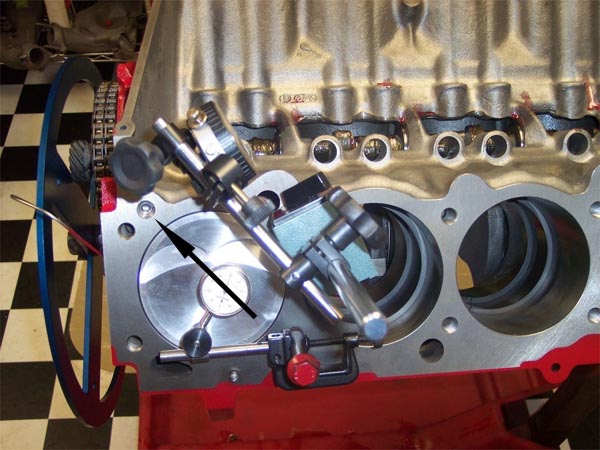

Notice black arrow pointing to plugged oil feed hole. When changing to Edelbrock heads this needs

to be plugged because there is not complete coverage of this oil feed hole which is a left over

design from 67-69 Buick 400-430 engines which used this hole for oil supply for rocker shaft

oiling. Buick 455 engines from 70-76 use pushrod oil (oil from the lifters) for lubricating the

rocker arms. This is only found on the #1 cylinder.

Notice black arrow pointing to plugged oil feed hole. When changing to Edelbrock heads this needs

to be plugged because there is not complete coverage of this oil feed hole which is a left over

design from 67-69 Buick 400-430 engines which used this hole for oil supply for rocker shaft

oiling. Buick 455 engines from 70-76 use pushrod oil (oil from the lifters) for lubricating the

rocker arms. This is only found on the #1 cylinder.

Flow Numbers as of 7-23-07

by George Nenadovich

Sunnen Pro-Flo 600, Altitude 15 ft, Temp 78 F

Heads were purchased as 60039...unassembled as noted above,

assembled with SS swirl polished valve and very minor clean-up around bowl

area and ports.

| Lift |

Intake CFM |

Exhaust CFM |

| 0.050 |

36 |

26 |

| .100 |

66 |

55 |

| .150 |

96 |

81 |

| .200 |

126 |

103 |

| .250 |

158 |

123 |

| .300 |

192 |

139 |

| .350 |

220 |

152 |

| .400 |

247 |

162 |

| .450 |

266 |

170 |

| .500 |

279 |

175 |

| .550 |

278 |

180 |

| .600 |

276 |

183 |

| .650 |

276 |

184 |

| .700 |

278 |

185 |

- Assembly Notes: When installing the new heads, order Trick

Flow head bolt washers, TFS-51400418

set of 20 runs about $8

- Intake manifold bolts will 3/8-16 by 1 3/4 long. Use washers with

bolts. Torque to 25 ft-lbs after oiling bolt threads and under bolt heads.

- Check guide plates for proper clearance. I used 3/8 pushrods and

due to the stamping process, guide plates were 0.378 which meant an interference

fit. I used as small die grinder to widen the guide plate opening to 0.384

- Tighten upper head bolts to 110 ft-lbs and lower ones to 100 ft-lbs.

Always, lube bolt threads with 30 weight oil and also under bolt heads

to get accurate torque readings.

- Before you order pushrods....order GHP-3520 pushrod length measuring

tool from Gessler Head Porting

and follow the instructions for properly measuring pushrod length.

Notice two scratches/lines indicated by red arrows. This

is the result of the extra thickness of the cast aluminum valve covers and

the wide roller rockers. This indicates that both rockers arms have to be

shaved on one side. This only happens on the top valve cover bolt holes

on each end of the valve cover.

Notice two scratches/lines indicated by red arrows. This

is the result of the extra thickness of the cast aluminum valve covers and

the wide roller rockers. This indicates that both rockers arms have to be

shaved on one side. This only happens on the top valve cover bolt holes

on each end of the valve cover.

Completed shaving each roller rocker arm. The angle of the

material to be removed should match the angle of the thread boss/valve cover

gasket as shown below the rocker arms. In this case....Poston cast aluminum

covers and 1.6 Summit roller rockers, about 3/16 x 3/16" area was removed.

Completed shaving each roller rocker arm. The angle of the

material to be removed should match the angle of the thread boss/valve cover

gasket as shown below the rocker arms. In this case....Poston cast aluminum

covers and 1.6 Summit roller rockers, about 3/16 x 3/16" area was removed.

Slightly different angle showing the ground area.

Slightly different angle showing the ground area.

Notice black arrow pointing to plugged oil feed hole. When changing to Edelbrock heads this needs to be plugged because there is not complete coverage of this oil feed hole which is a left over design from 67-69 Buick 400-430 engines which used this hole for oil supply for rocker shaft oiling. Buick 455 engines from 70-76 use pushrod oil (oil from the lifters) for lubricating the rocker arms. This is only found on the #1 cylinder.